Description

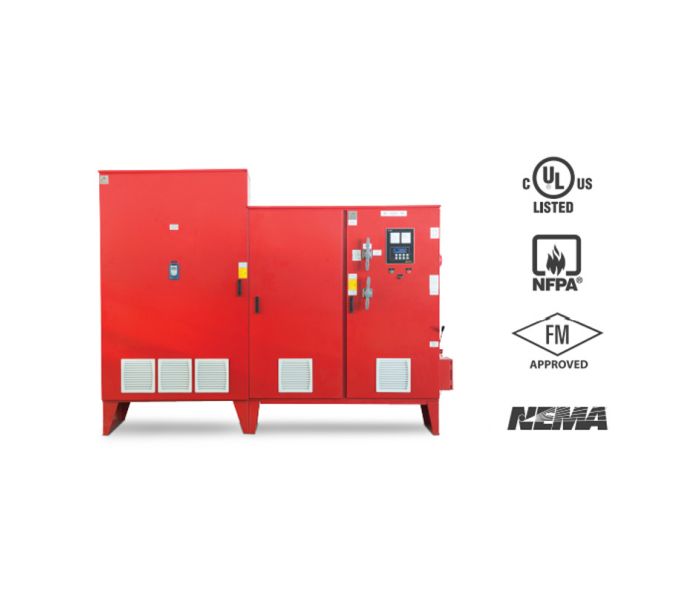

NAFFCO Variable Frequency Drive Controllers are listed by Underwriters Laboratories (UL file number EX15064), in accordance with UL 218 (Standard for Fire Pump Controller), UL 508 (Standard for Industrial Control Equipment), NFPA 20 (National Fire Protection Association Standard for the Installation of Stationary Pumps for Fire Protection), NFPA 70 (National Electric Code) and applicable NEMA standards. Also approved by FM approvals (Factory Mutual), in accordance with FM standard 1321 / 1323 (Approval Standard for Controllers for Electric Motor-Driven and Diesel Engine Driven Fire Pumps). This controller is completely wired, assembled, programmed and tested at the factory before shipment, and ready for immediate installation.

STARTING TYPE OPTIONS:

NFY-VFD-DOM1 – VARIABLE SPEED W/ DIRECT ONLINE

NFY-VFD-SSM1 – VARIABLE SPEED W/ SOFT STARTER

ENCLOSURE OPTIONS: NEMA 4, NEMA 4x, NEMA 12